BEARCAT Instrumentation Test Engine

Inhaltsverzeichnis

- 1 Introduction

- 2 BEARCAT: A heavily instrumented Turboshaft

- 3 Example Images

- 4 Location

- 5 Engines which can be included in the facility

- 6 Type of modifications to engines

- 7 Probe specifications

- 8 Type of running to be considered

- 9 Indicative Engine Operating Environment

- 10 Expected Availability Date

- 11 Further information

Introduction

BEARCAT (for "Banc d’Essai Avancé pour la Recherche en Combustion et Aérothermique des Turbomachines") is a brand new turboshaft developed by SAFRAN-Tech, the R&D Center of the SAFRAN Group. BEARCAT is based on a MAKILA engine, a turboshaft developed by Safran Helicopter Engines (formerly Turboméca) and powering the H215 and the H225 Airbus Helicopters. BEARCAT has been developed in order to perform fine characterization of aero-thermal phenomena occurring within the combustion chamber and the High Pressure Turbine as well as their interactions. Therefore, BEARCAT differs from a standard test engine by the implementation of metrologies, in order to perform both steady and non-steady flow measurements which will be used to validate CFD codes and models. Therefore, BEARCAT could be used in the framework of fundamental studies, such as aerodynamics, thermics, combustion, acoustics, … as well as applied studies (sensors, materials, technologies, fuels, …). Indeed, thanks to the high degree of instrumentation, BEARCAT allows for the fine characterization of the test conditions and then contributes to the TRL enhancement of the tested technology.

BEARCAT: A heavily instrumented Turboshaft

BEARCAT is based on a MAKILA turboshaft.

The main purpose of BEARCAT is to generate an extensive data base which will be used to validate CFD codes, transient thermal codes, … and models. To address these concerns, it was felt necessary to instrument an engine within the hot temperature / high pressure region, by means of a metrology generally implemented on partial test rig and allowing a fine characterization of local unsteady characteristics of encountered flows. The instrumentation implemented on BEARCAT is summarized in table 2. Special attention was given to the characterization of secondary flows and boundary conditions in terms of temperature (mass and flow) and pressure, in order to characterize the machine performances.

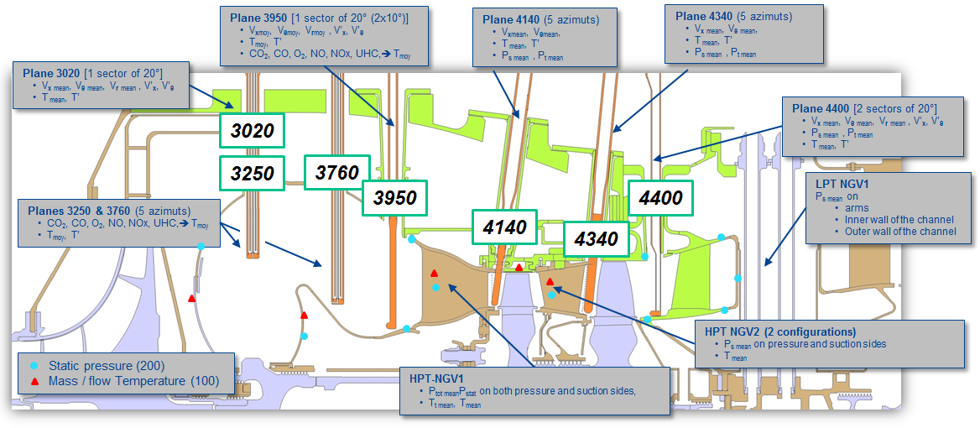

On the other hand, the main flow can be investigated by means of probes implemented at 7 sections, from the Combustor inlet to the HP-Turbine outlet. Each section, or plane, has its own respective instrumentation (indicated in figure 2). Note that only one probe can be implemented at a time. The probe is being automatically traversed into the engine thanks to a versatile device called SYSPAC. This device performs also the data acquisition, independent of the probe type, it performs the data analysis and associates the data to the main engine data collected from the Human Machine Interface.

A perfect tool for fundamental studies

Thanks to the implemented instrumentation BEARCAT is really dedicated to fundamental studies. Indeed, BEARCAT allows for both steady and non-steady flow measurements (velocity, static or dynamic pressure, temperature, chemical species …) coupled with mass temperature or local stress. A classical metrology allows the determination of detailed performances as well as the fine knowledge of the average experimental conditions generating the investigated flows (collected from the HMI). In total, 23 physical access ports es are available on BEARCAT at the level of the Combustor and the HP Turbine, allowing the implementation of a wide range of metrologies, yet existing or to be developed.

A technological platform for Technology Readiness Level (TRL) enhancement

BEARCAT is also well suited for TRL enhancement tests? with many advantages. BEARCAT is a real engine with a real and well-known engine environment in terms of thermodynamics, mechanics, vibrations, chemistry …. It gives also the opportunity to eventually quantify the impact of the implemented technology: sensors, equipment, material, fuel, design, materials, process, …. by means of the implemented metrology. Also suited as a platform for sensor validation ???

Example Images

Figure 1: Cross-sectional view of a MAKILA 2A1 engine

Figure 2: Partial cross-section of BEARCAT showing the instrumentation implementation.

Location

Tests to be carried out at SAFRAN Group in house facilities in XXXX, France.

Who the facility will be offered to:

- Sensor manufacturers ??

- Engine OEMs ??

- Universities that are looking to utilise the engines to validate some of the work they are doing ??

- Students and Graduates ??

- ??

Engines which can be included in the facility

- Exclusively built for the BEARCAT test engine ???

Type of modifications to engines

Any modification or customizing possible?

Probe specifications

A heavily instrumented turboshaft: 385 measurement points.

- 7 sections (23 physical access ports), from Combustor inlet to HP Turbine outlet, fitted with probes.

- Both steady and unsteady measurements available.

- Well suited to fundamental studies such as CFD validation.

- Well suited to technological works such as TRL enhancement on a real turboshaft engine.

- First tests planned in October 2020.

| Meas. type | Qty | Meas. type | Qty |

|---|---|---|---|

| Temperature (mass + flow) | 48 + 78 | 5-Hole probes (2D-3C) | 4 |

| Deformation gauges | 16 | 3-Hole probes (1D-2C) | 13 |

| Static Pressure | 185 | LDA (2D-2C) | 3 |

| Total Pressure | 14 | Gas analysis (1D) | 11 |

| Unsteady pressure | 4 | Rotation speed | 2 |

| BTC | 4 | Optical plug | 1 |

Table 2: Main Instrumentation implemented on BEARCAT.

Type of running to be considered

Please add any other running uses that we have not covered.

| Length | 1836 mm | Weight | 279 kg |

| HP turbine | ~ 33000 RPM | OPR | 11 |

| Output shaft | ~ 23000 RPM | max Cont. | 1410 kW |

| Torque | ~ 900 Nm | Take-Off | 1563 kW |

| Turbine Entry T° | > 1100 K |

Table 1: Main characteristics of the Makila 2A1 engine.

Indicative Engine Operating Environment

add here

Expected Availability Date

First tests planned in October 2020.

Further information

SAFRAN Group are happy to discuss individual requirements with interested parties. Please contact XXXXXXXX on XXX@XXXXXXX.XX. We also welcome any feedback, and would be interested to hear any alternative proposed uses for the facility.

About SAFRAN Group

[add some 3 line about about the AIM the SAFRAN Group.]

EVI-GTI Provides this site to allow members to collaborate in pre-competitive technical areas. EVI-GTI will not be held responsible for loss or corruption of data; inaccuracies in content or actions of members posting to this area.