Compressor mass flow

Inhaltsverzeichnis

Introduction

Gas turbine engine certification requires good knowledge of the compressor surge margin. While the working and surge line are easily measurable on a test rig, mass flow measurement is not usually possible in the installed condition. This gives rise to uncertainty on the actual surge margin available for operability manoeuvres. A method to derive the mass flow parameter during transient operation is being proposed. Validation and standardisation of this method would provide a complementary tool for compressor specification. Feedback is requested so as to better evaluate the usefulness of such a standard within the gas turbine community.

Background

Gas turbine engine certification requirements stipulate that the compressor should have sufficient margin to avoid surge during operation. Hence proper characterisation of a compressor's surge line in its installed condition is inherent to the certification process.

Compressor mapping on a dedicated test rig is a common practice. This type of test is the basis for verification that the physical unit corresponds to the engineering design and compliant with the specifications. The test rig is sufficiently equipped such that accurate measurements can be made at any working point on the corresponding compressor map. This makes it practical to verify the compressor characteristics namely: reduced mass flow vs pressure ratio, reduced mass flow vs speed, pressure ratio vs speed.

Installation of the compressor into its working environment (a gas turbine for example) may modify its characteristics in unexpected ways due to interactions with the engine architecture features such as a swan-neck duct, bleed holes, back pressure from the internal air circuit, variation in clearances etc. Operating at different altitudes and ambient conditions may also give rise to Reynolds number effects, adversely influencing the compressor surge margin. This rig to engine variation is often difficult to quantify during operability testing, principally because an independent measurement of the mass flow is not possible in the installed condition.

A method for calculating mass flow on an installed compressor is being proposed. The technique relies on measuring the local Mach number at a given segment (between two stator blades) of know area to compute flow. This derived parameter, together with pressure, temperature and shaft speed measurements enable the positioning of the dynamic compressor running line during transient manoeuvres. Thus the compressor's surge-free zone can mapped.

Laying out a validated guideline for this method could be a way to complement existing industry standards. This would delineate a recommanded practice guide for (1) the design and calibration of instrumentation, as well as (2) the implementation of a dedicated calculation routine. Substantiation would be achieved by running a series of back to back compressor tests permitting the comparison between test rig and test bed results.

Aerodynamic Theory

In this section, the principles for deriving the compressor map characteristics using common aerodynamic equations is set out.

The derivation is based on the knowledge of the below parameters:

| Parameter | Symbol | Units | Measuring device |

|---|---|---|---|

| Total Pressure | Pt | bar | Total Pressure Probe |

| Static Pressure | ps | bar | StaticPressure Probe |

| Total Temperature | Tt | K | Thermocouple |

| Shaft speed | n | rpm | Rotating speed sensor |

| Specific Heats | Cp, Cv, γ, R | - | Thermodynamic Tables |

| Section Area | A | m2 | Physical geometrical measurement |

The following nomenclature is used in the subsequent equations:

M = mach number

c = speed of sound (m/s)

ts = static temperature (K)

v = local velocity (m/s)

ṁ = mass flow (kg/s)

ρ = density (kg/m3)

Hence using the principles of one dimensional aerodynamic flow the local velocity and mass flow may be derived as follows

velocity:

M = fn(Pt, ps)

c = fn(T)

mass flow:

ts = fn(Tt,M)

ρ = fn(ps,ts)

ṁ = ρAv

Compressor maps are normally presented using reduced parameters, thus:

Reduced Mass Flow = fn(ṁ,Tt,ts,Pt,ps)

Pressure Ratio = Pt/Ps

Shaft speed = fn(n,Tt)

Practical considerations

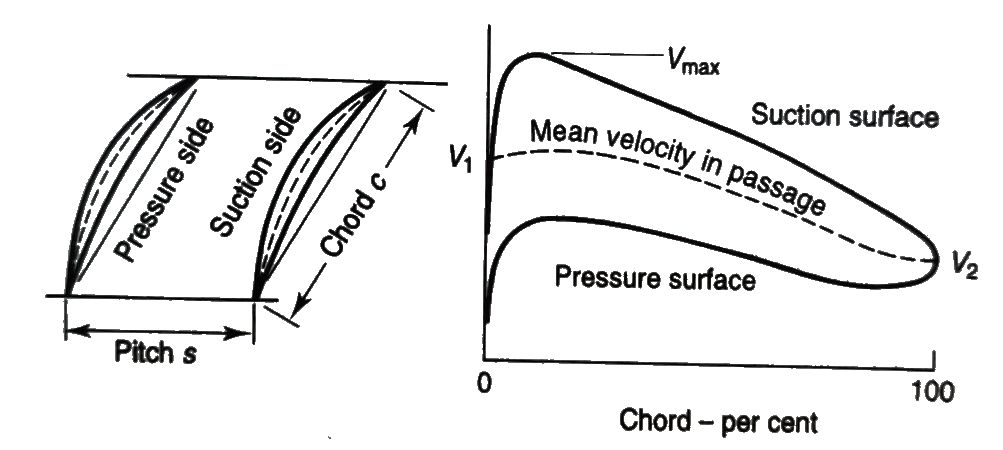

The simple derivation discussed above does not take into account the three dimensional nature of the flow through the compressor. Pressure and temperature profiles will exist along

• the blade height • in span-wise (pitch-wise) direction between two stators • along the chord length

Measurement corrections

In practice, an accurate mass flow measurement is not necessarily required. A representative mean value which can be correlated to the test rig data would suffice. Three to four measurements along the blade height would be enough to reconstruct the vertical velocity profile while the pitch wise variation can be assumed.

Due to the physical construction of the measuring probe, it is unlikely that all the pressure and temperature measurements will be placed at the same % chord depth. Some scaling factor will be required to 'adjust' the measured values and bring them to the same section plane.

Instrument intrusion effects

Pressure and temperature measurements are usually recorded by means of intrusive probes fitted between two successive stator vanes. This obstructs the flow in the segment in which they are inserted but will not significantly impact the overall compressor mass flow. A correction factor to scale back the measured velocity to the unobstructed condition is to be determined. The total compressor flow is then equal to the corrected flow through the measuring section x (number of stator vanes - 1)

Temperature probe response

Temperature measurement by thermocouple has a non negligible response time lag. This is not normally critical for steady state operation when the operating condition can be sustained for a few minutes.

During operability testing, fast acceleration and deceleration may be carried out in order to achieve significant operating point excursions with respect to the compressor's working line. In such a case, the temperature measurement may lag such that the value observed at the surge condition is out of phase.

The below methods should be considered to minimise the bias that could be induced by the temperature measurement:

• slow acceleration / deceleration manoeuvres for operability testing • fast response temperature measurement • quantify the impact of a temperature bias on the calculated mass flow and translate this into a measurable and acceptable uncertainty

Preliminary test program

The different phases proposed for this project are outlined as follows: Phase I

• Identify an instrumentation set which would enable the measurement of the critical parameters. The selection should be such that it is practical to mount on a compressor • Derive methods for calculating the mean velocity based on area averaging of the temperature and pressure gradients along the compressor vane • Perform a series of steady state readings on a rig mounted compressor. The readings will be compared to the calibrated rig instrumentation to validate coherence between the two. At this stage ::::Computational Fluid Dynamics (CFD) representations of the vane flow may be used to validate the mean velocity methods. • Validate the coherence of the results in transient conditions. This can be done on the compressor rig using the same method as above

Phase II

• Replicate the results on an engine-mounted compressor. (Initially on a sea level testbed) The pre-calibrated instrumentation shall be mounted on the engine such that the mass flow in the 'as installed' condition can be measured • Validate coherence of the results in transient conditions • Additional testing may be carried out on an ATF and in flight

Standardisation

tbd

Concluding remarks

The discussion above proposes a method to complement axial compressor operability testing procedures. The theory is based on fundamental aerodynamic principles, however its implementation is challenging due to the 3D nature of the flow through a compressor.

A methodical experimental study would be required so as to validate and normalise this process if it were to be accepted as a standard industry procedure.

Opinions and comments from gas turbine engine experts, developers as well as users is being sought in order to better evaluate the:

• added value that the proposed procedure could bring to the industry • constraints and feasibility of the proposed procedure